Why Choose the Right Laminating Adhesive for Your Projects?

Choosing the right Laminating Adhesive can be the key difference in project success. John Smith, an expert in adhesive technology, once said, “The right adhesive can elevate a project from mundane to magnificent.” This highlights the importance of selecting the appropriate adhesive for your specific needs.

Laminating Adhesives come in various types, each with its strengths and weaknesses. For instance, some adhesives provide strong bonds but might have longer curing times. Others bond quickly but may lack flexibility. Understanding these traits can help in making informed decisions. The perfect adhesive isn’t always what meets your eye at first.

It’s crucial to evaluate your project's requirements before deciding. Consider materials, intended use, and environmental factors. An ill-suited adhesive may lead to delamination or other issues. Choosing wisely ensures durability and professionalism in your work. Reflecting on your choices is necessary for ongoing improvement in your projects.

Advantages of Using the Right Laminating Adhesive in Various Industries

Choosing the right laminating adhesive can significantly impact various industries. In packaging, for example, a strong adhesive ensures the longevity of labels and protective films. This leads to better product presentation and consumer trust. The right adhesive helps maintain packaging integrity, avoiding spills or degradation during transport.

In the automotive industry, laminating adhesives play a crucial role in the assembly of components. They provide essential bonding for parts that resist vibration and temperature changes. An unsuitable adhesive can compromise safety and performance. Small mistakes here can lead to costly recalls and damage to a brand's reputation.

Construction also relies heavily on the right laminating adhesive. From flooring materials to walls, the adhesive must endure various environmental factors. Poor choices may result in delamination and structural problems. Reflecting on past projects allows teams to learn which adhesives perform best under specific conditions.

Understanding Different Types of Laminating Adhesives and Their Properties

Choosing the right laminating adhesive is crucial for any project. Different types of adhesives offer unique properties and benefits. For instance, thermal laminating adhesives rely on heat to activate. They create a strong bond, making them ideal for professional documents. However, they require precise temperature control.

On the other hand, cold laminating adhesives provide ease of use. These are perfect for projects that need quick assembly. They don't require heat, but they might not hold as strong under pressure. Furthermore, some adhesives are water-based, which makes them safe and environmentally friendly. Yet, their adhesive strength can be less than solvent-based options.

Understanding the differences helps in making informed choices. Many users overlook the importance of testing adhesive on a small scale first. The right choice can elevate the quality of a project. But sometimes, a poor selection leads to frustrating results. Research and experimentation are essential for achieving desired outcomes.

Comparison of Different Types of Laminating Adhesives

Industry Standards for Laminating Adhesives: Ensuring Quality and Performance

When selecting laminating adhesives, it’s vital to adhere to industry standards. These standards help ensure both quality and performance. For instance, the American National Standards Institute (ANSI) outlines specific requirements for laminating adhesives used in various applications. Meeting these standards is essential for achieving optimal bonding and durability.

Recent reports indicate that nearly 40% of adhesive failures stem from inadequate adhesion due to subpar materials. Inappropriate adhesive selection can lead to costly reworks and project delays. Adhesives should be tested under various environmental conditions to ensure reliability. Factors like temperature changes and moisture can drastically impact their performance.

Another crucial aspect is understanding the substrates you’re working with. Different materials may require unique adhesive properties to perform effectively. Industry data suggests that 70% of applications benefit from customized formulations tailored to specific project needs. Choosing the right adhesive is not a one-size-fits-all solution. This variability highlights the need for careful assessment and testing prior to full-scale application.

Why Choose the Right Laminating Adhesive for Your Projects? - Industry Standards for Laminating Adhesives: Ensuring Quality and Performance

| Adhesive Type | Temperature Resistance | Application Method | Cure Time | Bond Strength |

|---|---|---|---|---|

| Water-Based Adhesive | Up to 80°C | Roller/Brush | 30 minutes | Medium |

| Solvent-Based Adhesive | Up to 120°C | Spray/Brush | 15 minutes | High |

| Hot Melt Adhesive | Up to 150°C | Extrusion/Manual | Immediate | Very High |

| UV-Curable Adhesive | Up to 100°C | Coating | 2-5 seconds | High |

| Epoxy Adhesive | Up to 120°C | Mixing | 24 hours | Very High |

Impact of Adhesive Selection on Project Longevity and Durability

Choosing the right laminating adhesive can significantly impact the longevity and durability of your projects. Reports indicate that adhesive quality is a key factor in material performance. A study by the Adhesive and Sealant Council suggests that nearly 70% of failures in laminated products are due to poor adhesive selection. This highlights the importance of carefully evaluating what type of adhesive to use.

Different projects require unique adhesive properties. For instance, moisture-resistant adhesives are crucial for outdoor applications. In contrast, heat-resistant adhesives are vital for high-temperature environments. Failure to choose appropriately can lead to issues such as delamination and material degradation. A recent analysis found that projects using high-quality adhesives typically last 50% longer than those that do not. This discrepancy is often due to environmental factors affecting inferior adhesives.

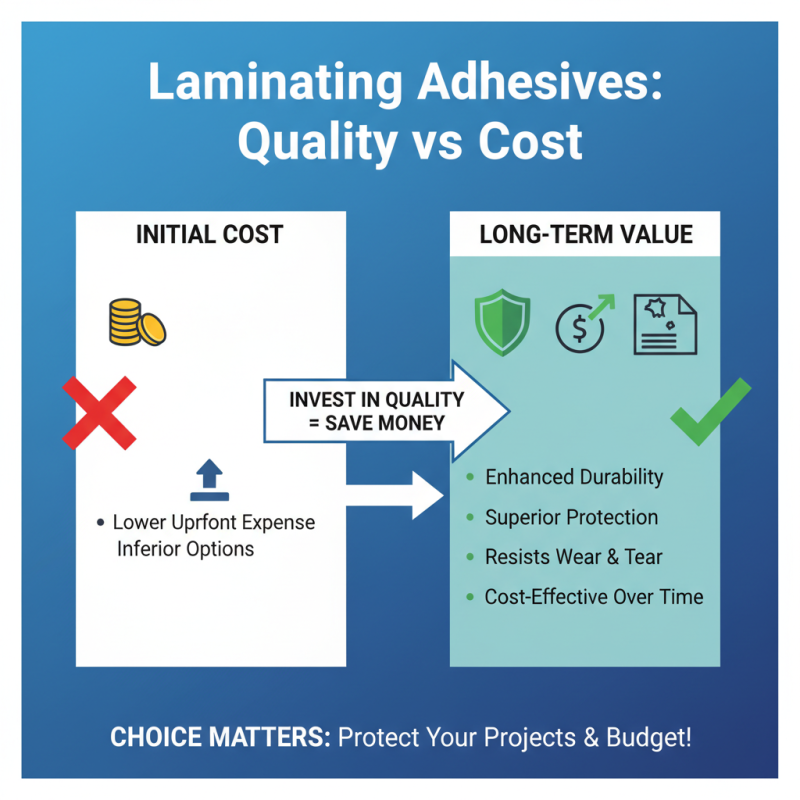

Reflections on project outcomes can reveal unexpected challenges. Sometimes a decision made in haste leads to costly repairs. The initial cost of better adhesives might deter some, but the long-term benefits outweigh short-term savings. Projects could face premature failure if the adhesive does not hold up under stress. Overall, a thoughtful approach to adhesive selection is essential for ensuring lasting quality in laminating projects.

Cost-Benefit Analysis of Choosing the Right Laminating Adhesive for Projects

Choosing the right laminating adhesive can significantly impact your project’s outcome and budget. The initial investment in high-quality adhesive may seem steep. However, the benefits often outweigh the costs. A suitable adhesive can enhance durability and protection, preventing damage over time. It ensures that your project can withstand wear and tear better than those using inferior options.

Consider the hidden costs of choosing the wrong adhesive. Inadequate lamination can lead to issues like peeling or bubbling. These problems may force you to redo the project, increasing overall expenses. You might save money upfront but could pay more later. Reflect on how often you might have to replace lesser quality work. Similarly, time is money. The extra hours spent fixing mistakes are costly.

Choosing the right adhesive is about balancing cost and effectiveness. It's essential to research before making a decision. A cheaper option may be tempting, but the long-term benefits of a quality adhesive are clear. A smart choice today can save frustrations tomorrow. Evaluate your specific needs and think critically about the type of projects you're tackling.

Related Posts

-

10 Tips for Choosing the Right Laminating Adhesive for Your Projects?

-

Top Uses and Benefits of PUR Hot Melt Adhesive in 2025

-

How to Use Polyurethane Adhesive for Strong and Durable Bonds

-

How to Choose the Right Crylate Adhesive for Your Project Needs

-

2026 Best Polyester Hot Melt Adhesive Options for Your Projects?

-

How to Choose the Best Beer Bottle Labeling Adhesives for Your Brewery